-

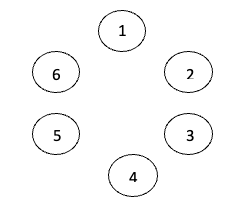

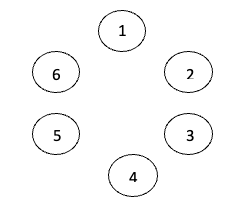

- Identify fasteners as specified. Locate six (6) of each of the 3/8 x 16 bolts, washers and nuts located in the assembly area.

- Assemble fasteners in test plate. Assemble one (1) of each of the bolts, washers and nuts in each of the circular holes.

-

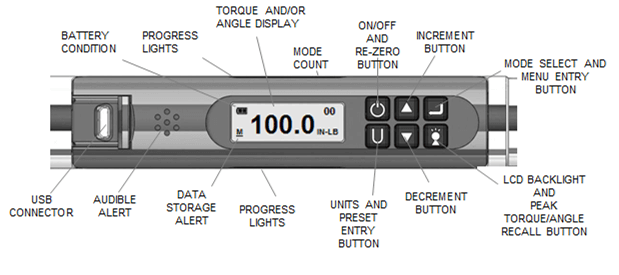

- Verify proper torque on torque instrument

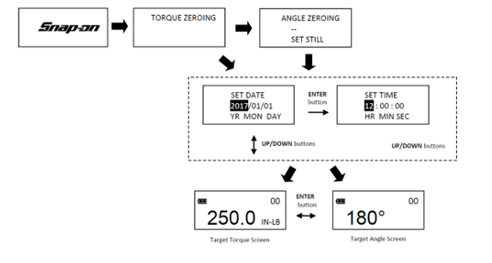

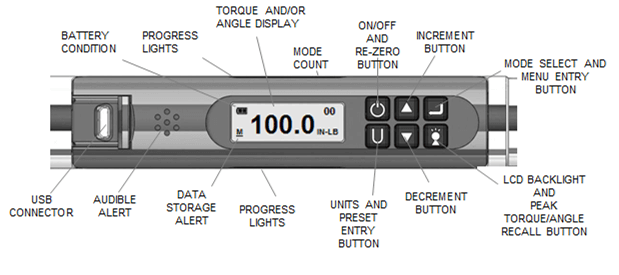

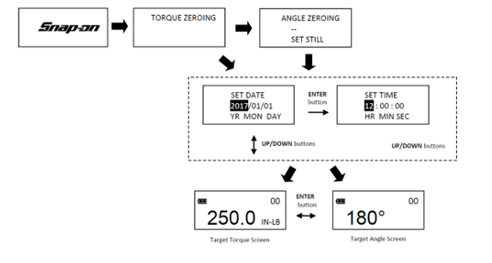

Turn On Wrench: While holding wrench still, momentarily press POWER button. Snap-on logo will be displayed followed by torque and angle re-zeroing screens (if angle mode has been previously selected).

-

- Torque Fasteners in a star pattern as specified

TORQUE MODE

-

-

- If needed - Set Target.

Use UP/DOWN buttons to change TORQUE target value.

-

-

- Select Units of Measure.

Repeatedly press UNITS button while on target TORQUE screen until desired units are displayed.

-

-

- Apply TORQUE.

Grasp center of handle and slowly apply torque to fastener until progress lights display green and a ½ second audible alert and handle vibration alerts you to stop.

-

-

- Release TORQUE.

Note peak TORQUE reading flashing on LCD display for 5 seconds.

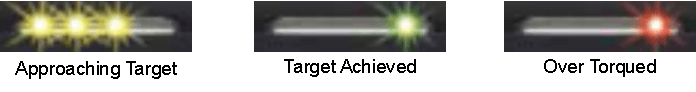

PROGRESS LIGHTS

Yellow - First light indicates 40% of target torque or angle reached. Second indicates 60% of target reached. Third indicates 80% of target reached.

Green - Indicates target torque or angle reached.

Red - Indicates exceeded torque or angle target plus 4% or exceeded maximum Preset target.

-

- Notify judge upon completion of the assignment.

Penalties may be assessed for improper assembly of a fastener, improper inputting of torque settings into the torque instrument, and/or application of torque to fastener.

|